-

Posts

78 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Events

Yamaha Racing News.

Media Demo

Store

Collections

Classifieds

Posts posted by Jack R1

-

-

The 'plastic' ABS ones will be OEM

-

1

1

-

-

9 minutes ago, slice said:

Lovely set of machines Jack, I imagine the "Human female" has an annoying whine tho, both my boy's had it as well, fixed it with a large helping of fuel.

I found Milk has very good lubricating qualities to stop the whine

-

2

2

-

-

Heres a quick history of the bikes I've owned (as you can see its a Yamaha fest with a few rogue ones thrown in). Apart from when I was 16 / 17 there has always been a Yamaha in the garage

Suzuki TS50ER

Suzuki TS125X

Kawasaki AR125

Yamaha RD350LC

Yamaha FZR250RR

Yamaha FZ600

Honda CBR400R

Yamaha FZR600

Ducati M600

Yamaha R1 (2000)

Yamaha R1 (2002)

Suzuki GSXR600 (2003)

Yamaha R1 (2004) x 2

Yamaha R1 (2007)

Yamaha R1 (2009)

Human Female (2014) - Current

Suzuki SV650 (2005) - Current

Suzuki SV650 (2006) - Current

Yamaha TR1 (1983) - Current

Yamaha SRX600 (1985) - Current

-

4

4

-

-

On 11/03/2016 at 10:59 AM, jimmy said:

C'mon Jack, you've kept us hanging around for 10 days now....we need updates

I'm self employed and work has been crazy so done very very little for some time now. On top of that, race season started for us last weekend so preparation for that has taken up quite some time. I promise to get back to this asap

I'm self employed and work has been crazy so done very very little for some time now. On top of that, race season started for us last weekend so preparation for that has taken up quite some time. I promise to get back to this asap

I do now have the single carb conversion kit arrive so may start tinkering very soon

-

1

1

-

-

-

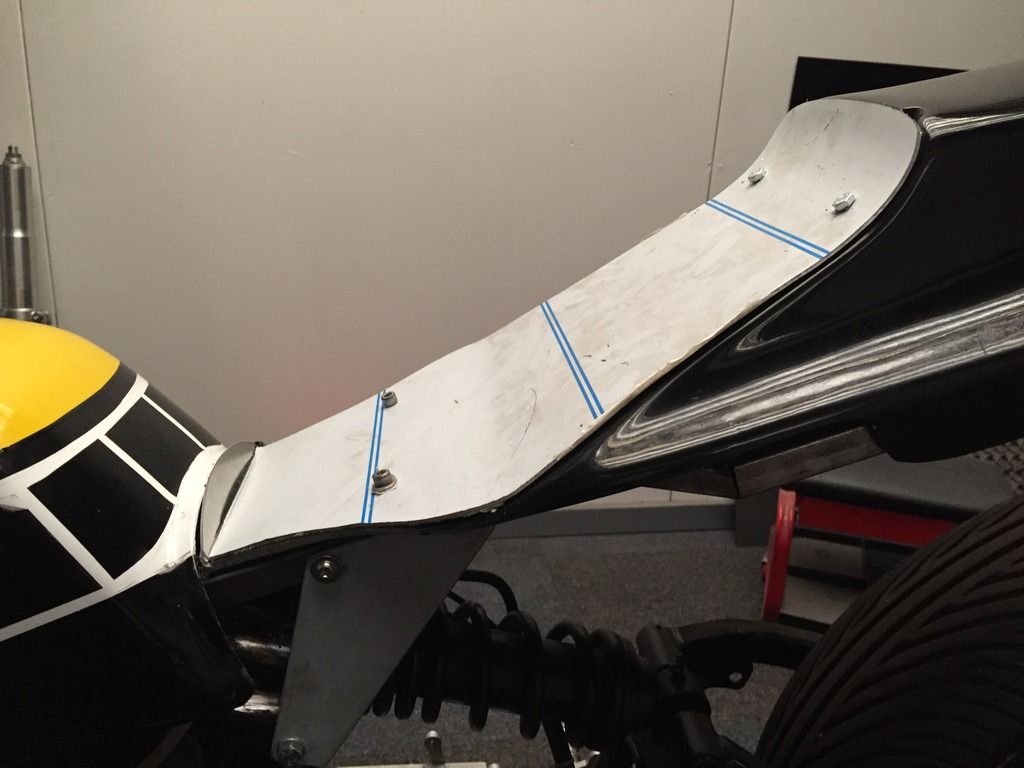

Oh it has been thought through. It will be more obvious once the finished shape of the foam is done

Bare in mind the bike currently sits with no forks in it. The sitting position is flat once the bike stands on two wheels

-

You've lost me now. Why will I be sliding around on that seat ? All you can see is the aluminium base that the foam will be over and the seat cover over that ?

I have a feeling we may be talking at cross purposes

-

A 6mm bolt is obiously only 10mm in diameter and approx 3 or 4mm high ? On top of that there will be a dome of resin. The seat foam and seat cover will then take care of the rest. That seat foam will be a layer of dense on the bottom and another layer of a softer at the top

If you look at the seat they are also positioned toward the front and rear of the seat. The front where the most of my weight will be is going to be thicker than that at the back

-

I'm using standard M6 bolts then welding an aluminium u bracket over them to stop them turning (going to add resin as a secondary fix). The seat foam will easily mould over the heads

-

I've already drilled the subframe

-

Not the most exciting few weeks as I've had to actually do some paid work but.....

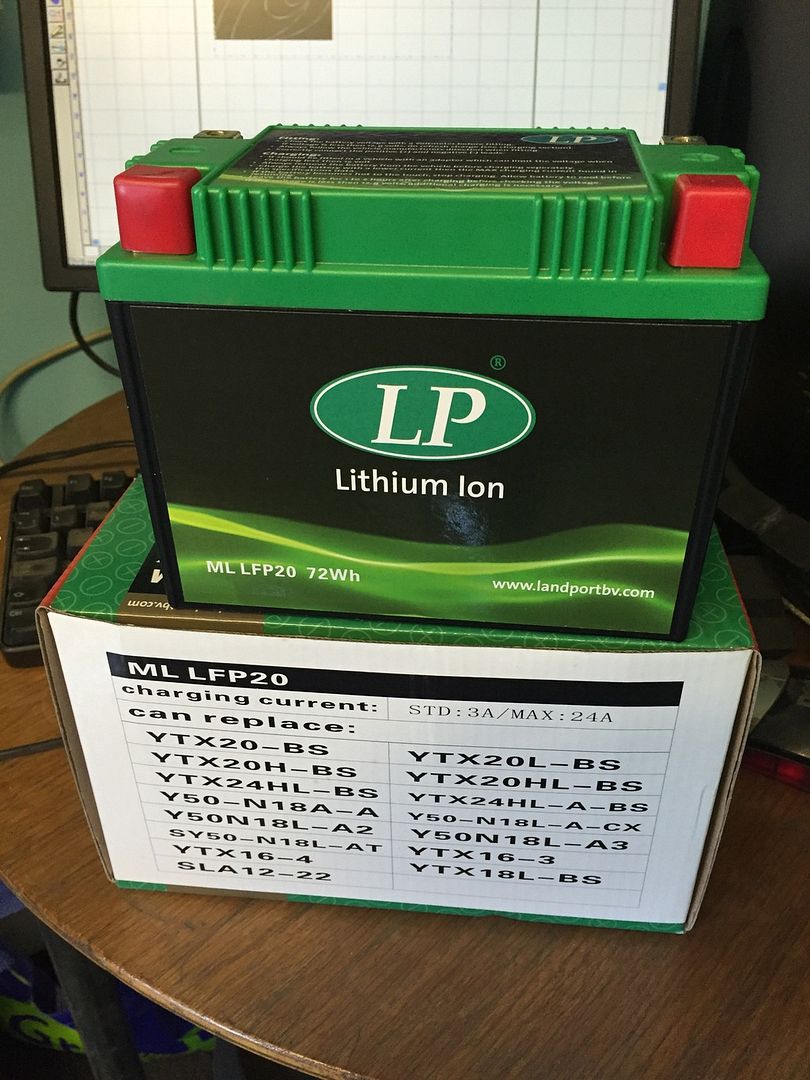

Battery has turned up from Italy. All 1.7Kg and 330CCA's worth

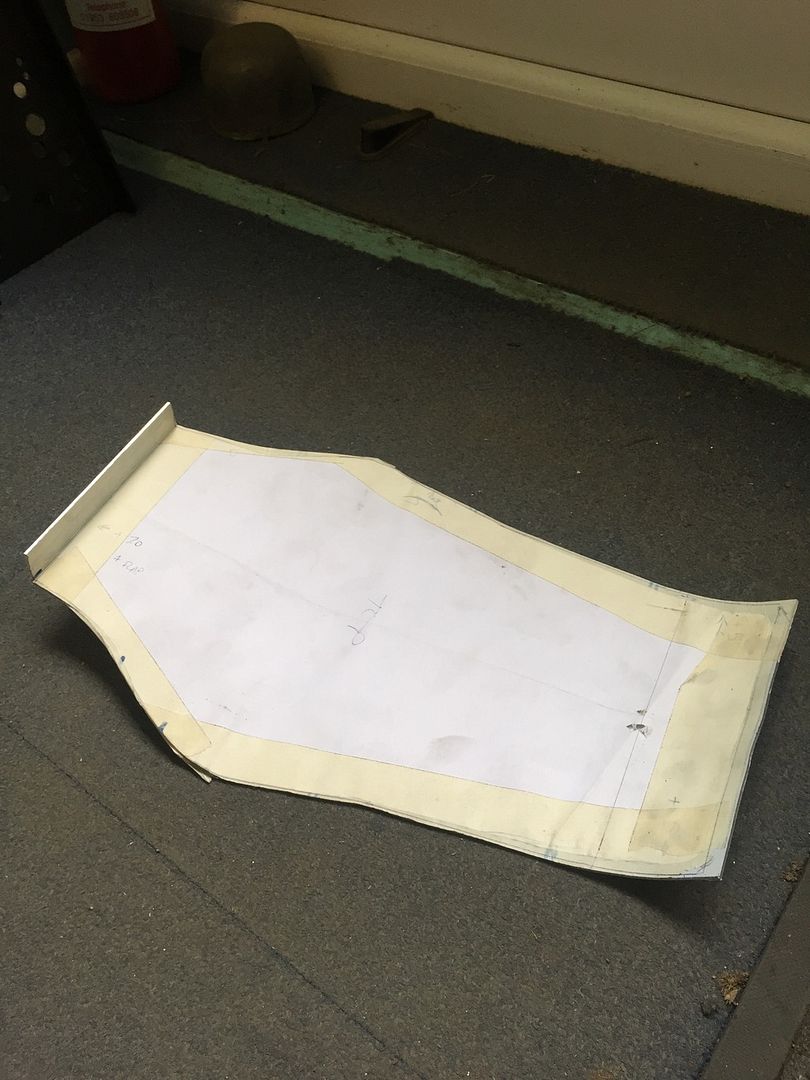

Good old paper template for seat base

And the nearly finished aluminium version (just have to resin in the bolts to stop them turning once the seat foam and cover have been fixed on)

-

£140 on a battery - ouch !

-

If its anything like the bigger Xv's then its a piece of piss. Have mine out and back in again within the hour

-

-

-

LOL, they are only there to dry fit, they are easy to spin on and off quickly. There will be bosses made up that go into the box section and nylocs where the bosses aren't feasible

-

-

-

-

Fantastic, thankyou

-

Quick question about the braided sleeving..... I was looking at this on the bay of fleas a few days back but wasn't sure how the sizes worked.

The 6mm for example, is that the size of yhe sleeving while layed flat or the diameter of the cable you are sleeving ?

-

Nice project. Please tell me you are going to lose those bar ends ?

-

On 18/01/2016 at 10:03 PM, fabiostar said:

brilliant... keep it up cause im dying to see how this turns out

Work has slowed down due to my bread earning work being manic - bloody customers lol

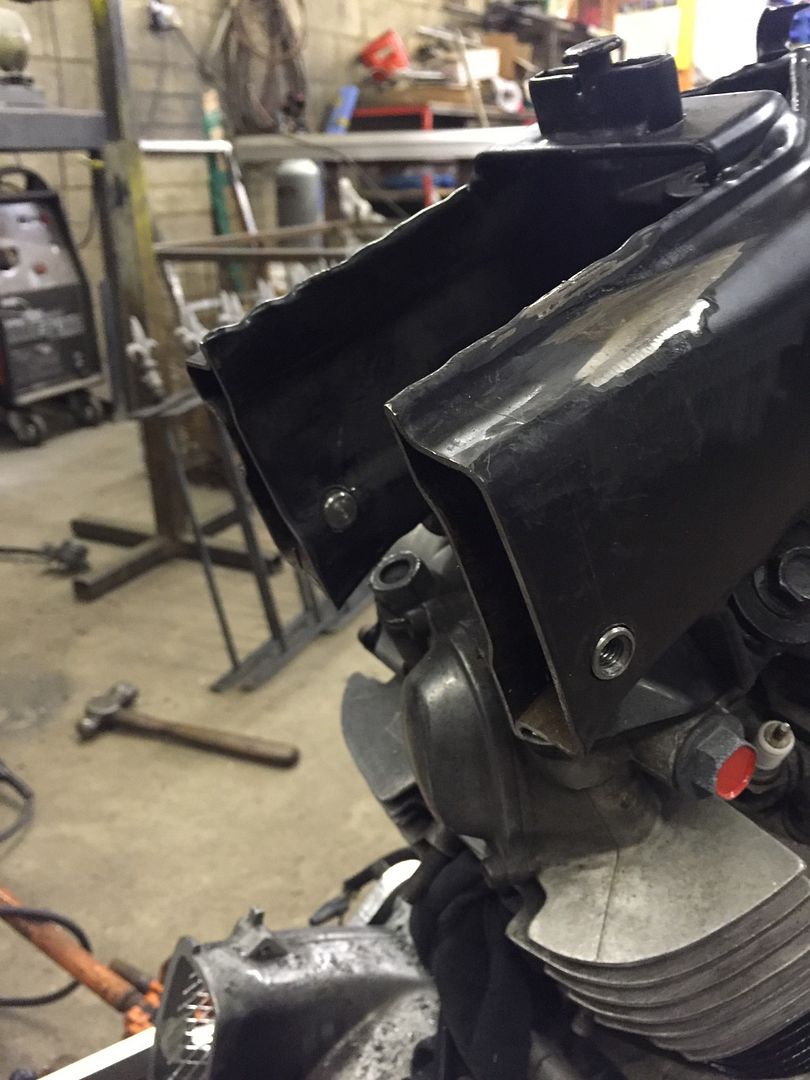

Starting to think about the subframe..... Needed a secure fixing within the frame so turned up some threaded bosses to be welded through the frame for the lower subframe fixing point

-

Another bit of mesh to tie things up a little (probably have a small bit on the rear hugger if and when I acquire one). Mesh and mudguard will both be black

http://i295.photobucket.com/albums/mm122/Jack-R1/Mobile%20Uploads/image_zpsysvbt3e0.jpeg

http://i295.photobucket.com/albums/mm122/Jack-R1/Mobile%20Uploads/image_zpsysvbt3e0.jpeg

-

2

2

-

Dt125re reztoratio.

in Projects

Posted

I'm sorry but the heat of the oven will not have caused the bearings to seize in. That's caused by hamfistedness

The oven will only have been 180degrees so I can't see how that would cause them to seize